When it comes to transformers, there is a crucial element that plays a significant role in their efficiency and performance: silicon steel. Silicon steel, also known as electrical steel or transformer steel, is a specially processed material that is widely used in the construction of transformers. Its unique properties make it an ideal choice for transforming electrical energy, and its usage has revolutionized the field of power distribution.

What Is The Silicon Steel Used In Transformers?

Silicon steel is a type of alloy specifically designed for its electrical and magnetic properties. Its unique composition, which includes a high percentage of silicon, allows it to exhibit low core losses and high magnetic permeability. This means that it can efficiently transfer electrical energy from one coil to another, minimizing energy losses in the process.

The Manufacturing Process of Silicon Steel

Silicon steel used in transformers undergoes a unique manufacturing process to enhance its electrical and magnetic properties. Let's take a closer look at how this remarkable material is produced.

Raw Material Selection: The first step in manufacturing silicon steel is selecting the appropriate raw materials. The primary ingredient is, of course, silicon, which is combined with iron and other elements to achieve the desired composition. The silicon content can range from 1.5% to 4.5%, depending on the specific application and performance requirements.

Melting and Casting: Once the raw materials are selected, they are melted in a furnace at extremely high temperatures. This molten alloy is then cast into thin slabs or ingots, which serve as the basis for further processing.

Hot Rolling: The next stage in the manufacturing process is hot rolling. The cast slabs or ingots are reheated and passed through a series of rolling mills, where they are progressively reduced in thickness. This process helps align the crystal structure of the steel and refine its grain orientation.

Annealing: After hot rolling, the silicon steel undergoes an annealing process. Annealing involves subjecting the material to controlled heating and cooling cycles to relieve internal stresses and enhance its magnetic properties. This step is crucial in achieving the desired low core losses and high magnetic permeability.

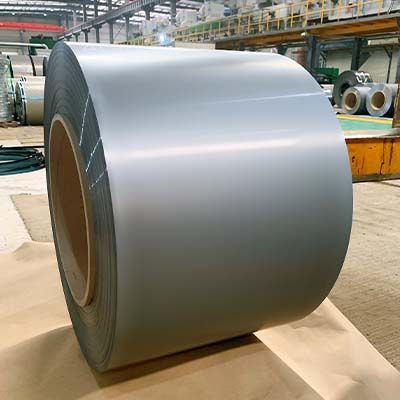

Insulation Coating: To further improve the performance of silicon steel, it is often coated with a thin layer of insulation. This coating serves as a barrier between the steel laminations, reducing eddy current losses even further. Various types of coatings, such as oxide or varnish, can be used, depending on the specific application.

Cutting and Stacking: The final step in the manufacturing process involves cutting the silicon steel into individual laminations and stacking them to form the transformer core. These laminations are carefully insulated from one another to prevent the formation of circulating currents that could lead to energy losses.

Silicon Steel For Transformers

Main Properties Of Silicon Steel Used In Transformers

Low Core Losses: Maximizing Efficiency

One of the most significant advantages of silicon steel used in transformers is its ability to minimize core losses. Core losses refer to the energy dissipated in the core material due to hysteresis and eddy currents. Hysteresis losses occur when the magnetic domains within the material realign as the alternating current flows through the transformer. Eddy current losses, on the other hand, result from circulating currents induced in the core due to the changing magnetic field.

By using silicon steel, transformer manufacturers can significantly reduce these core losses. The high silicon content in the steel increases its electrical resistance, thus minimizing eddy current losses. The unique grain orientation achieved through the manufacturing process also reduces hysteresis losses. As a result, transformers constructed with silicon steel operate at higher efficiency levels, translating into cost savings and reduced environmental impact.

High Magnetic Permeability: Enhancing Performance

Another critical property of silicon steel used in transformers is its high magnetic permeability. Magnetic permeability is a measure of how easily a material can establish a magnetic field within itself when exposed to an external magnetic field. A higher permeability allows for stronger magnetic flux and better coupling between transformer coils.

Silicon steel's high magnetic permeability ensures efficient energy transfer by reducing magnetic flux leakage. This means that a larger portion of the energy generated by the primary coil reaches the secondary coil, minimizing power losses. The high permeability also facilitates the compact design of transformers, as less steel is required to achieve the desired performance.

Conclusion

As the demand for energy-efficient solutions continues to grow, silicon steel remains at the forefront of transformer technology, ensuring efficient and reliable power transmission. With low core losses and high magnetic permeability, silicon steel enables transformers to operate at higher efficiency levels, resulting in significant cost savings and environmental benefits.