In the realm of electrical engineering, the pursuit of efficiency is of paramount importance. The grain oriented silicon steel sheet is a key component that plays a crucial role in enhancing efficiency. This remarkable material has revolutionized the performance of electrical devices, enabling them to operate with reduced energy loss and improved magnetic properties.

Manufacturing Process Of Grain Oriented Silicon Steel Sheets

The production of grain oriented silicon steel sheets involves several intricate steps to achieve the desired magnetic properties. Let's take a closer look at the manufacturing process:

Melting and Casting: The process begins with the melting of raw materials, including iron, silicon, and other alloying elements, in an electric arc furnace. The molten steel is then cast into slabs or thin strips.

Hot Rolling: The cast slabs or strips are hot rolled to reduce their thickness while maintaining the desired crystallographic orientation. This step helps align the crystal grains in the direction of rolling, enhancing the magnetic properties of the steel.

Annealing: After hot rolling, the steel undergoes annealing, a crucial process that involves heating it to high temperatures and then cooling it slowly. Annealing relieves internal stresses, allows grain growth, and promotes the desired crystallographic texture, further improving the magnetic characteristics.

Insulation Coating: To prevent electrical shorts between adjacent laminations, grain oriented silicon steel sheets are coated with a thin layer of insulating material. This coating is typically made of an inorganic substance like oxide or phosphate.

Shearing and Stacking: Once the insulation coating is applied, the sheets are sheared into appropriate sizes and stacked to form laminated cores. These cores are used in the construction of transformers and other electrical devices.

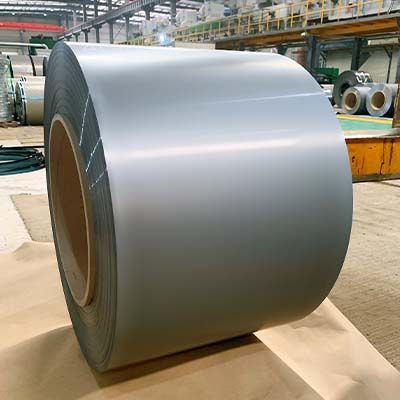

grain oriented silicon steel sheet

Advantages Of Grain Oriented Silicon Steel Sheets

The use of grain oriented silicon steel sheets offers numerous advantages, making them highly desirable for electrical applications. Let's delve into the key benefits provided by these remarkable materials:

Reduced Core Losses: Grain oriented silicon steel sheets exhibit significantly lower core losses compared to conventional steels. This results in improved energy efficiency and reduced wastage, leading to substantial cost savings over the operational lifespan of electrical devices.

High Magnetic Permeability: The unique crystallographic orientation of grain-oriented silicon steel enables it to exhibit high magnetic permeability. This property allows for efficient flux distribution, minimizing energy losses and enhancing the overall performance of electrical components.

Low Hysteresis Losses: Hysteresis losses occur due to the cyclic magnetization and demagnetization of magnetic materials. Grain oriented silicon steel sheets possess low hysteresis losses, ensuring minimal energy dissipation and maximizing the efficiency of electrical devices.

Excellent Dimensional Stability: Grain oriented silicon steel sheets demonstrate exceptional dimensional stability, even under varying operating conditions. This property ensures the structural integrity of electrical devices and helps maintain their optimal performance throughout their service life.

Accurate Magnetic Properties: The manufacturing process of grain oriented silicon steel sheets allows for precise control over their magnetic characteristics. This enables electrical engineers to design and construct devices with accurate magnetic properties, improving performance and reliability.

Wide Availability: Grain oriented silicon steel sheets are readily available in the market, making them easily accessible for various electrical applications. Their widespread availability ensures a consistent supply chain, facilitating seamless integration into different devices and systems.

Applications Of Grain Oriented Silicon Steel Sheets

The unique magnetic properties of grain oriented silicon steel sheets make them indispensable in various electrical applications. Let's explore some of the key areas where these sheets find extensive use:

Power Transformers

Power transformers are vital components in electrical power transmission and distribution systems. They facilitate the efficient transfer of electrical energy by stepping up or stepping down voltage levels. Grain oriented silicon steel sheets are employed in constructing transformer cores due to their low core losses and high magnetic permeability. These sheets enable transformers to operate with improved efficiency and reduced energy wastage.

Electric Motors and Generators

Electric motors and generators rely on the conversion of electrical energy into mechanical energy and vice versa. Grain oriented silicon steel sheets play a crucial role in constructing motor and generator cores, enabling efficient energy conversion. Their superior magnetic properties minimize losses, enhance motor performance, and improve overall system efficiency.

Inductors and Chokes

Inductors and chokes are passive electronic components that store and release energy in magnetic fields. Grain oriented silicon steel sheets are widely used in the construction of inductors and chokes due to their low hysteresis losses and excellent magnetic permeability. These sheets ensure minimal energy dissipation and enhance the performance of these components.

Magnetic Amplifiers and Reactors

Magnetic amplifiers and reactors are vital components in power electronic circuits. They regulate and control the flow of electrical energy by utilizing magnetic fields. Grain oriented silicon steel sheets are employed in these applications to minimize core losses and improve the efficiency of the circuits.

Instrument Transformers

Instrument transformers are devices used to measure and protect electrical systems. They provide accurate voltage and current measurements for monitoring and protection equipment. Grain oriented silicon steel sheets are extensively utilized in constructing instrument transformer cores, ensuring precise and reliable measurement of electrical parameters.

Conclusion

Grain oriented silicon steel sheets have revolutionized the efficiency and performance of electrical devices, power transformers, and related equipment. Their unique composition, manufacturing process, and magnetic properties make them indispensable in electrical engineering.

With their remarkable advantages and wide availability, these sheets continue to empower engineers to create more efficient and sustainable electrical solutions for a brighter future. Please feel free to contact us for further information about the top-quality grain oriented silicon steel sheet.